Acids are corrosive and often irritating substances. Some acids arise from the reaction of the corresponding anhydride with water, others from the reaction between a non-metal and hydrogen.

Seven Fluss, with its historic brand Tecno Fluss, provides complete PVC dosing lines and monoblocks for the dosage of Acids and bleaches.

The panels of the structures and frames, which can come into contact with the product, are made of anti-corrosion PVC.

Some details such as nozzle terminals, depending on the application, can be made of special materials such like titanium. The lines are equipped with hoods to extract acid fumes or vapors. Possibility of integrating the dosing line with the capping station.

Production ranges from 2000 to 6000 pcs/h.

1 liter containers or 5, 10 e 25 liters jerry cans can be dosed with automatic or semi-automatic systems.

Manual cycle

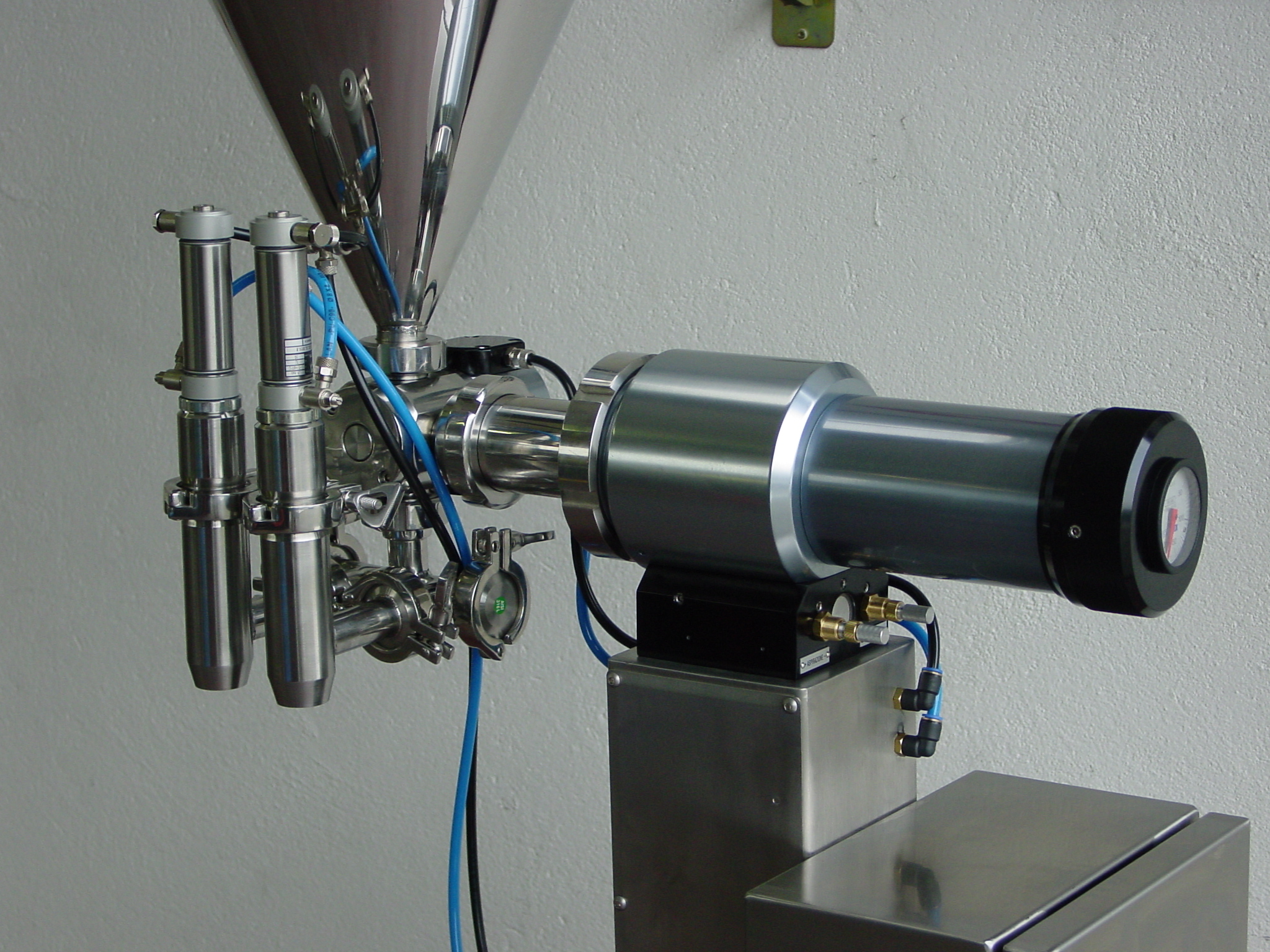

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Dosing and capping line Mod. MR-4 MTS-1

Tecnofluss builts also complete lines with mixer, turboemulsifier for products preparation.

Acetone is a colorless and flammable liquid used as a solvent in cosmetics to remove nail polish.

Seven Fluss with its dosing system Tecno Fluss, produces volumetric dosing machines with completely pneumatic operation, in semi-automatic version or integrated into complete filling and capping lines.

The TVA head, suitable for dosing liquid products, is controlled by springs that act under the pressure of the dosing piston and allow a precise and fast dosage of the product without draining; the shut-off nozzle, while closing on the bottom of the cannula, enables the dosage in narrow neck containers.

Customized solutions for filling, capping and labeling, both linear and rotary.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.V.A.

Automatic valve. Suitable for dosing liquid products.

NOTES: Product loading from the hopper or pipe inlet from the drum.

Application with nozzle no-drip nozzle, this application can be put on automatic systems.

The Chemical Additive is in liquid form and is a compound that improves the characteristics of the substance to which it is added.

Seven Fluss, with its historic brand Tecno Fluss, realizes pneumatic volumetric dosers and filling and capping systems in the chemical sector.

These products require special care during the manufacturing process: with our semi-automatic volumetric dosers and filling and capping systems this is possible.

Our lines can be configured with linear multi-nozzle filling modules equipped with pneumatic or electronic dosers depending on the needs, while for capping it can be provided single-head turrets or with 3, 4 or 5 rotary heads depending on the speed required.

For the management of fragmented productions in a certain number of formats, we propose our MRM Multiformat module which does not require the replacement of the transport star, considerably reducing the format change time.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle.

This application can be put in line on automatic systems

Monobloc Multiformat Mod. MRM900V3

Liquid and semi-dense products dosage.

Dosing and capping line MR-4 MTS-1

Tecnofluss builts also complete lines with mixer, turboemulsifier for products preparation.

Filling line Mod. MR-4 Brushless

4 dosing nozzles, 1800 pcs/h

The aroma is the sensorial characteristic of a food given by certain substances contained in it. In the field of food industry, some substances are added to foods in order to reproduce certain Aromas.

Seven Fluss, with its historic brand Tecno Fluss, is specialized in the dosage of flavorings for the food sector.

All our dosing systems are carefully designed and manufactured with high quality materials to guarantee continuous productivity over time.

We offer customized filling and capping solutions to meet all your needs: from the semi-automatic dosing unit for smaller productions, to the complete line for more complex productions including possibility of format change.

Our equipment can be easily disassembled for cleaning operations.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing liquid products.

REMARKS: Hopper for product loading with possibility of product stirring by scraping blades and augerfiller.

Application with anti-drop shut-off nozzle, etc. this application can be put in line on automatic systems.

Filling line Mod. MR-4 Brushless

Dosing with 4 nozzles, output 1800 pieces/h

Filling line on unit MR-4 and capping unit MTS-1

Quick and precise dosing of syrups with output up to 50 pieces per minute

Filling and capping line

Heated hopper with horizontal-blades stirrer. Output 3000 pieces/h

Cosmetic Creams can be dosed together with gel or together with another cream different in type, consistency, color or fragrance. This offers to the end customer a double variety of choice, in a single package.

Seven Fluss, known in the packaging sector for Cosmetics thanks to the historic Tecno Fluss brand, makes dosing machines with an innovative system that allows to dose together different types of creams or creams and gels,

together inside the same package, both for spiral effect that in layers.

Depending on the type of production, our experts will direct you to the most suitable filling solution for your needs: from the semi-automatic dosing system to fully automatic plants for productions up to 2000 pieces per hour and more.

The filling system for multicolored spiral cream includes a rotation device and twist movement made with a brushless servo motor that allows to obtain that particular effect. Customized multi-outlet nozzle allows the dosage of 2-3-4 colors together.

All our dosing machines are built with high quality materials, with the parts in contact with the product in Aisi 316 steel and completely removable for cleaning.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with no-drip nozzle, this application can be put online on automatic systems.

Dosage with VM 300 T.B.P. unit

Working table with rotary system and nozzle connected to n°2 dosing units Mod. VM 300 T.B.P.

Cosmetic Cream is a dense or semi-dense product that can be applied onto the face or the body, depending on the type of product.

Seven Fluss, specialized in this field since many years with its brand Tecno Fluss, makes filling and capping systems for every type of Cosmetic Cream.

Our dosing systems can be linear with 2, 4, 6 or 8 nozzles or rotary, with containers conveying star and internal stations completely customizable.

For lower productions, we offer semi-automatic volumetric dosers with pneumatic operation, with the possibility of implementing different accessories to make the dosage phases simpler and more functional.

To meet the various needs of the market, where packaging is constantly evolving, Tecno Fluss has designed a multi-format system where the transport star regulates itself to the format of the container without needing to be replaced: thus allowing to reduce production time.

All parts in contact with the product are in stainless steel Aisi 316 and can be completely disassembled for cleaning.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with nozzle no-drip nozzle, this application can be put online on automatic systems.

Semi-automatic Dosing Machine Mod. VM300 T.B.P.

Automatic 4 Heads Capping Machine Mod. MTR-4 T4

4 Nozzles Cream Dosing Machine Mod. MR-4

Productivity: 3.000 pcs/h

Burrata is a fresh cheese, made of spun paste with an external appearance similar to mozzarella but with the characteristic apical closure. The peculiarity of Burrata is its heart of cream and stracciatella, prepared by hand-splitting the spun paste with added cream.

Seven Fluss – dosing system Tecno Fluss – is specialized in the dosage of Burrata for the food sector.

Through our volumetric dosing machines designed with specific nozzles for this type of product, it is possible to dose the stracciatella inside the burrata by maintaining the quality of the product and by speeding up the manufacturing process at the same time.

All our filling systems are entirely made in Italy. On request some tools can be adapted for Burratine.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing of dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with special nozzle for the dosing of burrata cheese with stracciatella .

Dosing machine Mod. VM-600 TBP

Special nozzle for Burratine cheese

The Butter, with its soft consistency and its solid appearance, is the fat part of the milk.

Seven Fluss, with its historic brand Tecno Fluss, is specialized in the production of machines and dosing systems for butter and other types of creamy dairy products for the food sector.

Thanks to our volumetric dosers with special feeding systems, we can keep the product at a temperature between 28 and 33° C by favoring it practicality and the production speed.

All parts in contact with the product are made of Aisi 316 stainless steel which can be easily removed and washed in the utmost hygiene.

Each dosing system is specifically designed according to specific customer requirements.

Made with the aim of promoting the quality and precision of dosing, Tecno Fluss filling and capping machines are a real guarantee over time.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Dosing with gun nozzle for decorations.

Dosing Group 12+12 nozzles Mod. GDV

Application on thermoforming machine

Dosing Group with 12 nozzles Mod. GDV

Application on thermoforming machine

Chemical Fertilizers are used to fertilize the soil with the nutritional elements present in them. Through a differentiation in their composition, they are made specifically to meet the needs of specific types of plants.

The Seven Fluss Group, with its historic Tecno Fluss brand, is a specialist in the dosage of Chemical Fertilizers.

From the simple semi-automatic volumetric doser to the complete dosing and capping line, which may be complete with labeling, we can meet all the production requirements in terms of performance and customer’s budget.

Lines with 2, 4, 6, 8 or 10 nozzles filling together with single-head or multi-head capping machine for the highest productions, solutions for products packed in both bottles and jerrycans.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle.

This application can be put in line on automatic systems

Filling and capping line

Good for dosing chemical fertilizer into conteiners and tanks.

Chocolate is widespread consumed throughout the world and it is certainly one of the most widely used products in the confectionery industry.

Seven Fluss – dosing system Tecno Fluss – is specialized in the production of dosing systems for chocolate in all its forms.

Through our volumetric dosers it is possible to keep the heating of all the parts in contact with the product constant, by means of a hot water circuit, and in this way you keep the chocolate fluid at the right point by enabling a very precise dosing.

For the chocolate cream instead, heating is needed only in the hopper.

Our equipment will allow you to increase production speed without ever forgetting the importance of your product. Dosing systems can be easily disassembled for cleaning operations.

On request we can supply applications with a spatula nozzle for filling or multi-nozzle distribution plates.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller, heated by electric heaters to water bath.

All the parts in contact with product are heated in order to keep a constant temperature.

Application with flat trowel nozzle for stuffing or multi-nozzles plates for product spreading etc. This application can be put in line on automatic systems.

Filling lines for pralines

Conveyor belt with stepper motor and possibility of adding 6 nozzles.

Filling line for 2-colours chocolate Mod. MR-2

Line output 1500 pieces/h . Suitable for the transport of glass jars from 100 ml to 1 liter and automatic loading for twist-off or pressure caps.

Cleansing Milk is a cosmetic product that gently removes impurities and makeup from the skin.

Seven Fluss, with the historic Tecno Fluss brand, produces semi-automatic volumetric dosers and complete linear or rotary filling, capping and labeling lines for Cleansing Milk for the cosmetic sector.

For a market where packaging is constantly evolving, our experts have designed a multi-format dosing system where the transport star is self-adjusting on the container format without needing to be replaced, both in a totally automatic electronic version and in a semi-automatic mode.

Ideal solution for third party producers.

Each of our filling and capping systems is carefully made with high quality materials to guarantee continuous production over time. Solutions made on specific customer’s request.

For a precise dosage and without product waste, Tecno Fluss dosers are what you need!

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with a shuttle-off nozzle. This application can be put online on automatic systems.

4 Heads Automatic Capping Machine Mod. MTR-4 T4

Dosing and Capping Machine Mod. MR-4 MTS-1

Tecnofluss realizes complete lines for mixing, turboemulsifier and product preparation.

Dosing and Capping Monobloc Mod. MRT-12

Dosage with no-drip nozzle.

Creams and ointments are dermatological preparations for topical use with anti-inflammatory, soothing, pain-relieving or healing properties. They have a dense or semi-dense consistency, they can be more or less viscous.

Seven Fluss, with its historic Tecno Fluss brand, produces filling and capping machines for creams and ointments.

Our pneumatic volumetric dosers are equipped with a specific head for dense and viscous products, ensuring the precision and accuracy of dosage and can be adapted to bottles and jars of any type.

We produce fully automatic lines with 1, 2, 4, 6 or 8 nozzle linear filling modules, combined with capper and rotary solutions complete with capping station with automatic cap feeding and placement. The lines can also be integrated with module for pick&place of lid under the cap for the jars.

To meet the needs of a constantly evolving market, we have designed a multi-format filling and capping system where the transport star adjusts itself to the size of the bottle, significantly reducing format changeover time.

All parts in contact with the product are in Aisi 316 stainless steel.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller. Application with anti-drop shut-off nozzle. It can be installed onto automatic lines.

Semi-automatic dosing machine Mod. VM300TBP

Automatic 4-heads capping machine Mod. MTR-4 T4

4-nozzles filling unit for creams Mod. MR-4

Output 3.000 pieces/h

For Food Creams we mean fluid or dense compounds, prepared by mixing milk, flour or other thickening agent with other ingredients that give it a flavor or aroma.

Seven Fluss – Tecno Fluss dosing systems – is specialized in the dosage of Creams for the Food and Gastronomic sector.

Semi-automatic and automatic dosing solutions for filling jars, cups, bottles, trays.

In automatic version, also with sealing station (from reel, pre-cut operculum or cover with induction).

If required by the product, we optimize the solution with the heating system for hopper and / or dosing part.

Filling and capping lines with automatic feeding and screwing of caps for bottles and jars in glass or plastic, rotary solutions with tray or bucket de-stacker and lids destacker, sealing station and lid closure.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with flat trowel nozzle for sandwiches stuffing etc.. This application can be put in line on automatic systems.

Blowing and filling line for glass jars

Blowing machine with twist overturn and unit for filling and capping model MRT-12 for twist-off cap

Blowing, filling and capping line

Trays line

Application on automatic lines, dosing machine with 2 or 3 nozzles with castle-latch for product spreading and dosing into trays. Output 2000 pieces/h.

Filling line on unit Mod. MR-2

Quick and precise dosing of food creams with output up to 40 pieces per minute

Filling line for Pesto sauce

Heated hopper with horizontal-blades stirrer

Dosing application on customer’s line

Castle-latch nozzle for product filling

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles dosing suitable for glass containers and capping with twist-off cap

Monoblock for filling and sealing Mod. TF-15

Suitable for conical and unstackable containers with pre-cut lid

Dosing machine Mod. VM-60 TBP

Installation onto packaging machine for trays

Desserts and Sweets in general end the meal on special occasions. There are now many types and versions of them, surely the sweetest are the stuffed ones!

Seven Fluss, with its Tecno Fluss dosing systems, provides supply systems suitable for Desserts filling, both semi-automatic and automatic.

Dosing units equipped with anti-drop nozzles and thread-cut nozzles for more viscous products, gun nozzles to fill and decorate manually but with dosing precision.

Multi-hole plates to distribute jam, cream or frosting on the surface of the cakes.

Automatic and semi-automatic lines for filling cups with creams or sour cream, for the distribution of jam on cakes, for dosing the topping over the already filled dessert, for filling molds with liquid chocolate.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with plate nozzle for cake stuffing etc.. This application can be put in line on automatic systems.

Application dosing machine Mod. VM 300 TBP

Plate nozzle Ø 200mm thread-cutter and anti-drop

Filling line for dessert

Installation of dosing machines on automatic lines

Stepper filling line

Line output 1500 pieces/h . Suitable for the transport of round or rectangular bowls.

Filling line Mod. MR-2

2-nozzles dosing suitable for containers in trays.

Dosing of 1 gram cherry topping

Application on packaging machine

The Foundation, available in different shades depending on the type of complexion and in different variations depending on the type of skin, is a cosmetic used to cover skin imperfections.

Seven Fluss – Tecno Fluss dosing systems – is specialized in solutions of dosing and capping for Foundation.

Wide range of applications, from semi-automatic pneumatic volumetric dosers to complete filling and capping lines. Linear solutions with monoblock dedicated to filling and monoblock dedicated to capping, or rotary solutions with dosing station and capping station on the same carousel.

Multiformat rotary line with self-adjusting star on the container that does not need to be replaced, by reducing format changeover time.

Robotic systems for handling and positioning of components such as caps, undercaps, capsules, sponges: they optimize the line and allow high production rates.

Possibility of adding heated systems consisting in hoppers with heating electric resistances and stirrers with scraping blades and thrust auger, dosing part made with heated double jacket.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with anti-drop shut-off nozzle. It can be installed onto automatic lines.

Kit for electric heating of all the parts getting in contact with the product to be dosed.

Dosing Belt ND-2000

Output 2500 pieces/h

Monoblock for filling and capping Mod. MRT 10-S

4 dosing syringes for liquid and semi-dense products

Fruit Juices, clear or with pulp, are the product derived from the processing of various fruits.

If you are looking for a dosing system for Fruit Juice, Tecno Fluss dosers of Seven Fluss Group are what you need.

Whether to be bottled at room temperature or warm, you can dose it with us.

Our filling and capping systems are carefully designed and manufactured with the aim of maintaining a precise and accurate final result, which can be achieved thanks to our knowledge and expertise in the food sector.

Seven Fluss, proposes from the filling system with semi – automatic volumetric dosers to massive – magnetic systems to meet the needs of high productions.

On request, our dosing machines can be integrated with heated dosing systems to keep the product at the required temperature.

All our filling and capping machines are made with high quality materials to guarantee continuous productivity over time.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

The Gel is a semi-solid compound deriving from the gelation of liquids by gelling substances. In pharmaceuticals it is used for topical use on the skin, in order to release active ingredients on the skin itself or to soothe and protect the skin.

Seven Fluss offers the Tecno Fluss brand volumetric dosers for precise and accurate dosing of the Gels.

We supply semi-automatic solutions and complete lines with multi-nozzle filler and capper. Automatic solutions can be linear or rotary. Possibility to automate the feeding and the placing of the cap within the capping machine.

All parts in contact with the product are in Aisi 316 stainless steel.

With our dosing systems applied to both semi-automatic machines and complete filling and capping lines, the accuracy and dosage precision is ensured. Our team of experts will help you to find the best solution according to your needs, in terms of productivity and available budget.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Dosing Group with 12 nozzles model GDV

Application on thermoforming machine

The Bubble Bath is a cosmetic product to cleanse the body to be dissolved in water, fluid and foamy.

For over 30 years, Seven Fluss – dosing system Tecno Fluss – has been producing complete filling and capping lines for cosmetic products such as Liquid Soaps, Bubble Baths and Body Cleaners.

Our experience allows a fast and precise dosing and the shut-off nozzle systems with diving cane allow to avoid the creation of foam during the dosing process.

It is possible to automate the feeding and closing of all types of caps: screw-in, flip-top, with pumps or goose beaks even if equipped with a plastic cannula.

Seven Fluss, with its historic brand Tecno Fluss, also produces rotary machines that can adapt to the needs of the market due to the continuous packaging change, by creating mono-blocks for multi-format productions without changing the container transport star.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass automatic valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper, with the possibility of stirring produced by scraping blades and cochlea.

Application with nozzle no-drip nozzle, this application can be put online on automatic systems.

Automatic 4 heads Capping Machine Mod. MTR-4 T4

Dosing and Capping Line Mod. MR-4 MTS-1

Tecnofluss is specialized in building complete lines, from the mixing, turboemulsifier and product preparation.

Dosing line Mod. MR-4 Brushless

Dosage with 4 nozzles, Productivity: 1.800 pcs/h

Dosing and Capping Monobloc Mod. MRT-12

Dosage with no-drip nozzle.

Monoblock for filling and capping Mod. MRT 10-S

4 dosing syringes for liquid and semi-dense products

The Gel is obtained from the gelling of liquids by gelling substances.

The Tecno Fluss volumetric dosers of the Seven Fluss group ensure a precise dosage of the Gel.

Accurate filling of the syringe is possible through the use of anti-drip and thread-cutter shut-off nozzles with a customized cannula according to the type of syringe.

The machine can be equipped with a syringe centering device. All parts in contact with the product are in Aisi 316 stainless steel.

Our experts will be at your disposal to study the best dosing solution according to your needs and to optimize your packaging procedures.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Dosing Unit VM 60 TVC

Special nozzle for dosing in syringes

The Chemical Detergents are in general liquid and are a mixture that often contains surfactants; they are used to wash and clean (not the human body).

Seven Fluss with its Tecno Fluss dosing systems, produces semi-automatic volumetric dosers and filling and capping systems for Chemical Detergents.

Solutions for foamy products equipped with diving nozzles to avoid the formation of foam during the dosing phase.

Solutions for closing the bottles with screwing head equipped with pneumatically controlled arms to close dispensers, pumps or thousand-line caps.

Complete dosing and capping solutions for products packed in both bottles and jerry cans.

For corrosive detergents we can produce plants in anti-corrosion materials such as PVC.

Manual Cycle

DOSING MACHINE WITH T.V.A. DOSING HEAD

Automatic valve. Suitable for dosing liquid products.

REMARKS: Hopper for product infeed or pipe union for direct suction from drums.

Application with anti-drop shut-off nozzle, it can be installed onto automatic lines.

Filling and Capping line for chemical detergents in bottles and canisters, with screw on and trigger caps

Automatic linear filling machine with 6 nozzles, equipped with flowmeters. Semiautomatic linear capping machine with double closing station: once for screw-on cap and once for trigger.

Filling and Capping Monobloc Mod. MRT-12

Dosage with anti-drop nozzles

Dosing and capping line Mod. MR-4 MTS-1

Tecnofluss builts also complete lines with mixer, turboemulsifier for products preparation.

Glues and Mastics are substances that allow to connect two bodies more or less strongly, when they are interposed between them.

Seven Fluss, with its historic Tecno Fluss brand, produces filling machines and complete systems for Glues and Mastics.

We create filling and capping systems that have been carefully designed for taking care of the product to be dosed during the whole production process.

Our TVC dosing head reaches high dosing precision with glue-type products. The shut-off thread-cut and anti-drip nozzle prevents dripping and product threads.

It is possible to provide heated hoppers and stirrers to keep the product homogeneous during the dosing process.

All Tecno Fluss filling systems are produced with high quality materials to guarantee productive continuity over time.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off nozzle.

This application can be put in line on automatic systems.

Monobloc Multiformat Mod. MRM-900

Mass dosing system. Prepared for automation with plug-in robot

Multiformat Module Mod. MRM 900 V3

Dosage and capping of vinyl glue. 1500 pieces / h

Multiformat Module Mod. MRM 900 V3

Dosing and capping of glue such like mastic in tin-plate pots.

Grated Cheese. The cheese is a product that is obtained from the coagulation of milk, excellent to consume on its own but capable of enhancing the taste of other dishes as a condiment, usually grating it to mix it or sprinkle it on the surface of the food.

Seven Fluss – Tecno Fluss dosing system – can supply rotary lines for filling with Grated Cheese

trays and cups complete with storage for containers and lids, nitrogen injection station and lid sealing under the lid, lid closure.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Filling and Sealing Monoblock Mod. SGR 12

Precise and quick dosage of grated cheese, powder or flakes. In modified atmosphere with thermosealing film and aroma preservation cover.

Output 3000 pieces per hour.

Hair Dye is a cosmetic product for coloring or bleaching hair.

For the hair stylist sector, there are different products that Sevenfluss – Tecno Fluss dosing systems – can pack with her own systems such as oxygenates, bleaches, biphasic restructuring creams, balms or oils.

The lines and rotary monoblocks are made to obtain the maximum performance on different types of containers: today it is possible to process different products and container formats during the day with solutions such as our multi-format monoblock, that allows a very rapid format change as it does not needs to replace the transport star.

All this makes it possible to satisfy even the needs of small production lots.

The multiformat monoblock can be supplied in a completely electronic version requiring minimum operator intervention.

With our experience we can offer appropriate solutions for all needs in terms of production and budget, with automatic or semi-automatic lines with filler equipped with one or more nozzles and capper with one or more heads, cap feeding and placing can be both manual or completely automated.

For small businesses, the semi-automatic volumetric dosing unit can be implemented with everything needed to optimize and simplify dosing performance: heated hopper with stirrer, heating kit for dosing part, anti-drip and thread-cut shut-off nozzle, strokes repeater etc…

All parts in contact with the product are in Aisi 316 stainless steel and can be completely disassembled for cleaning.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Automatic 4-heads capping machine Mod. MTR-4 T4

Filling and capping line Mod. MR-4 MTS-1

Tecnofluss makes complete lines with mixer, turboemulsifier for product preparation

Monoblock for filling and capping Mod. MRT-12

Dosing with anti-drop nozzles.

Monoblock for filling and capping Mod. MRT 10-S

4 dosing syringes for liquid and semi-dense products

Hand Cleaning Paste is a detergent compound with a dense consistency that also has abrasive characteristics suitable for removing stubborn dirt.

Seven Fluss, with the historic Tecno Fluss brand a, offers a wide range of dosing solutions, which can be integrated with capping, ranging from simple semi-automatic volumetric dosers to complete lines.

The TBP dosing head guarantees high dosing precision, the anti-drip and thread cutter shut-off nozzles ensure accurate filling without dripping and product threads. Possibility to add heating and stirring to the hopper for product loading.

Automatic solutions both linear, with monoblock dedicated to the filling combined with the capping machine, both rotary with filling and capping on the same carousel. Possibility of integrating de-stackers for buckets and lids.

MRM Multiformat module for managing different formats with the same star for all of them.

Depending on the configuration, the star can be adjusted manually or electronically in a fully automatic manner. Ideal solution for those who produce for third parties or manages productions fragmented among different formats.

All parts in contact with the product are in stainless steel Aisi 316 and can be easily removed for cleaning.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle.

This application can be put in line on automatic systems

Monobloc Multiformat Mod. MRM-900

Mass dosing system. Prepared for automation with plug-in robot

Room Fragrances are produced with different fragrances and can be found in various packaging solutions: small vials with essences to be dissolved in the diffusers, larger bottles with more refined aesthetics, in which to dip sticks.

Sevenfluss – Tecno Fluss dosing systems – manufactures pneumatic volumetric dosing units in semi-automatic version and complete filling and capping systems, for glass or plastic containers, for productions from 2000 to 3500 pieces per hour.

Filling monoblocks with pneumatic or electronic volumetric dosing units, dosing at bottle-neck, capping machines with automatic caps feeding and positioning for various types of closures, including crimping heads.

Automatic closed-circuit filling and capping lines with godet for the handling of particular bottle shapes.

Our experts are at your service to offer you the application that best suits your packaging needs.

Manual Cycle

DOSING MACHINE WITH DOSING HEAD MOD. T.V.A.

Automatic valve. Suitable for dosing liquid products.

NOTES: Product loading from the hopper or pipe inlet from the drum.

Application with nozzle no-drip nozzle, this application can be put on automatic systems.

Filling line Mod. MR-4 Brushless

4-nozzles dosing, output 1800 pieces/h

Multiformat Monoblock MRM900V3

Dosing, insertion of pad, automatic screwing

The Melted Cheese is a homogeneous, semi-fluid and viscous cheese mixture.

With our dosing systems, you can dosing melted cheese in a simple and fast way.

Experts always ready to recommend the specific dosing solution for the production needs of each customer: from the standard semi-automatic volumetric doser to the more complex automatic filling and capping line.

For this type of product we have studied a dosing system with heating integrated in the hopper so that the cheese is fluid to the right point for making a very precise dosing.

Based on the required speeds, we offer various solutions starting from the semi-automatic doser to real completely customized production lines for a wider production.

All our dosing systems are made with high quality materials to guarantee a machine long life.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Electronic dosing machine Mod. E 1000 TBP-3 with Brushless motor

Application of electronic axis system on thermoforming machine, shut-off thread-cutter nozzles.

Dosing of melted cheese at 80°C

The Ink can be both liquid or pasty and have the ability to fix on materials like paper or others, used for writing and printing.

Seven Fluss, with its historic Tecno Fluss brand, offers a lot of solution of dosing and capping for product like Ink: from semi-automatic volumetric dosers to complete automatic filling and capping lines.

The accuracy of the dosage is guaranteed by the anti-drop and thread-cut shut-off nozzles that we provide and from our special dosing heads that can change depending from the consistency of the product that you have to be dosed.

Possibility to keep the product mixed and homogeneous in the hopper with the addition of an agitator.

The entire dosing part can be completely disassembled for cleaning operations.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off nozzle.

This application can be put in line on automatic systems.

Monobloc Multiformat Mod. MRM900V3

Filling and capping line Mod. MR-4 MTS-1

Tecnofluss builts also complete lines with mixer, turboemulsifier for products preparation.

Filling and capping Monobloc Mod. MRT-12

Dosage with anti-drop nozzles

Gel is a semi-solid compound deriving from the gelation of liquids by gelling substances. In cosmetics it is used for topical use to hydrate or refresh or tone the skin. There are also Gels for fixing hair.

Seven Fluss with its Tecno Fluss dosing systems, guarantees a precise and accurate dosage of the Gels.

From semi-automatic volumetric dosers to complete lines with filler and capper. Possibility to integrate labeller, markers and metal detectors.

Automatic solutions, linear or rotary, may or may not include automatic cap feeding and placement within the capping machine. All parts in contact with the product are in stainless steel Aisi 316 and can be completely dismantled for thorough cleaning.

Get help from our team of experts to find the solution that best suits your needs, in terms of productivity and available budget.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with nozzle an-drip nozzle, this application can be put online on automatic systems.

4 Heads Capping Machine Mod. MTR-4 T4

Dosing and Capping Machine Mod. MR-4 MTS-1

Tecnofluss realizes complete lines for mixing, turboemulfier and for the product preparation.

Insecticides are chemical compounds, used to combat harmful insects.

Seven Fluss, with its Tecno Fluss dosing systems, creates filling and capping systems suitable for liquid Insecticides.

Our volumetric dosers guarantee high dosing precision both in the semi-automatic machine version and in the automatic filling monoblock version with 2, 4, 6, 8 e 10 nozzles, suitable for filling bottles, cans, metal cans.

The dosing solution can be completed with the capper to close screw caps, thousand lines caps, dispenser caps and triggers.

MRM Multiformat rotary module for filling and capping of different container sizes, without replacing the transport star, also equipped with a cannula stretching device for the pumps.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle.

This application can be put in line on automatic systems

Filling and capping line Mod. MR-4 MTS-1

Tecnofluss built also complete lines with mixer, turbomixer for products preparation.

Monobloc Multiformat Mod. MRM900V3

Inserimenti pompetta con stiratore

Module in line with 8 noozzel

Good for insecticides dosage

Intimate Cleansers are a liquid mixture of chemicals to clean the skin, with a slightly acidic pH, so they are very delicate.

Seven Fluss – Tecno Fluss dosing systems – is specialized in the dosage of Intimate Detergents.

Pneumatic or electronic volumetric dosers for precise dosage, anti-drip and anti-foam nozzles for accurate dosing.

Automatic filling and capping lines, linear or rotary, with automatic feeding for screw caps, flip-top caps, dispensers, pumps with plastic cannula.

Seven Fluss, also produces rotary modules for filling and capping of several format sizes with a self-adjusting transport star on the container, which results into a significant reduction of format change time

All the parts in contact with the product are made in stainless steel Aisi 316.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Multiformat Monoblock Mod. MRM 900 V3

System of product inclusion by pick and place

The jam is a product obtained from fruit, mixed and cooked together with water and sugar and thickened thanks to the action of pectin.

Seven Fluss, with its historic brand Tecno Fluss, is specialized in dosing and capping systems for jams and marmalades.

Solution optimization with heating and stirring in the hopper.

Application with multi-hole plates to evenly distribute the product on surfaces such as sweets and pies.

Multi-needle plates and special nozzles for jam injection into bakery products.

Semi-automatic solutions with dosing unit equipped with a specific head for dense products, complete linear or rotary automatic systems for filling and capping of jars, cups and trays.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Blowing and filling line for glass jar

Blowing machine with twist overturn and filling and capping unit model MRT-12 for twist-off cap

Blowing, filling and capping line

Line output 3000 pieces/h with metal detector and possibility of weight checking. Suitable for the transport of glass jars from 100 ml to 1 liter and automatic infeed for twist-off caps.

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles Dosing suitable for glass containers and capping with twist-off cap.

Dosing Group with 12 nozzles Mod. GDV

Application on thermoforming machine

Lasagne is a true symbol of traditional cuisine. A sheet of pasta that alternates with a filling that varies according to the different local traditions.

Seven Fluss, with Tecno Fluss dosing systems, doses the product evenly between one sheet and the other one so that the final result is comparable to an handmade product.

All parts in contact with the product are completely made of Aisi 316 stainless steel.

The usage of our automatic or semi-automatic dosing systems will allow you to precisely dose the product through special nozzles that will distribute it equally in any type of container.

Our filling, capping and sealing lines are particularly performing, especially on linear dosing systems or closed-circuit filling lines for only two operators.

A staff of specialists will be at your disposal to find the most suitable solution to your project.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off anti-drop nozzle. This application can be put in line on automatic systems.

Nozzle suitable for meat sauce and béchamel spreading

Line for spreading in trays for lasagne and gastronomic products

Chocolate is certainly one of the most used products in the confectionery industry.

Seven Fluss, with its historic brand Tecno Fluss, is specialized in the production of dosing systems for chocolate in all its forms.

Thanks to our dosing machines, you can dose your chocolate cream in just a few seconds: you will have simply to put the product into the hopper and due to our heating system, the cream will stay fluid to the right point for enabling a very precise dosing.

In addition there is the possibility of integrating a second doser for making Bi-Coloured Chocolate.

Our equipment will allow you to reduce the production time without ever forgetting the importance of your product.

Easily removable systems for cleaning operations.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with flat trowel nozzle for sandwiches stuffing etc.. This application can be put in line on automatic systems.

Filling line for 2-colours chocolate Mod. MR-2

Line output 1500 pieces/h . Suitable for transport of glass jars from 100 ml to 1 liter and automatic loading for twist-off and pressure caps.

The Lip Gloss is a cosmetic product used for the lips, in order to give them a shiny and wet effect by making them look fleshed out.

Seven Fluss, an expert in the field since years with the Tecno Fluss brand, produces special Lip Gloss dosing and capping machines for the cosmetic sector.

Depending on the production requirements, we offer from the standard semi-automatic volumetric doser to complete filling and capping lines with robotic systems that reduce packaging times.

Depending on the density of the product, on request it is possible to implement filling systems with a heated system using hoppers and double walls heated with electric resistances, by keeping the product homogeneous with the movement of the scraping blades of a stirrer with cochlea.

To make the dosing operations even more precise and fast, we also implement special cut-thread shut-off nozzles with suction for the classic sticks.

The rotary machines with special containment bushes for sticks can be equipped with robots or pick & place system for automatic loading and screwing of the brush.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with no-drip nozzle, this application can be put online on automatic systems.

Heating kit for all parts in contact with the product to be dosed.

VM 60 T.B.P. unit

Lip Gloss dosing system.

Dosing and Capping Machine Mod. MM-2

Productivity: 1.500 pcs/h with shuttle-off and no-drip nozzle

Dosing and Capping Machine Mod. MM-2

Productivity: 1.500 pcs/h with shuttle-off and no-drip nozzle.

Dosing unit VM 60 T.B.P.

Suction no-drip nozzle.

Lipstick is a softening and coloring cosmetic product for the lips, containing pigments, oils and wax.

Seven Fluss – Tecno Fluss dosing systems – manufactures complete systems,

from the fuser to pour the product to the molds in the filling line, up to the complete assembly made by robot or pick & place systems served by brushless servomotors.

The dosing temperature is very important but also the cooling during the packaging phases must be carefully studied, in order to avoid imperfections in the final product.

Systems with double walls heated by diathermic oil circulation or water bath with electric resistances.

All parts in contact with the product are in Aisi 316 stainless steel and can be easily removed for thorough cleaning.

For limited production, we are able to offer semi-automatic volumetric heated dosing units with TBP dosing head, specific for this type of products.

Manual Cycle

DOSING MACHINE FOR HOT PASTES

Gears dosing machine for hot pastes such like lipsticks and cosmetic products. Tank with fuser and agitator with scraping blades. Each of its parts has been carefully designed for making cleaning operations easy and quick.

Dosing unit VM 60 TBP

Lip Gloss dosing system.

The Seven Fluss Group, with its historic Tecno Fluss brand, offers a wide range of solutions for the dosage and capping of Pharmaceutical Liquids, more or less dense and viscous, more or less fluid.

We have studied three different types of dosing heads to adapt our volumetric dosing unit to the different types of products: liquid, dense and pasty.

All parts in contact with the product are in Aisi 316 stainless steel. The dosing part of the machine can be completely disassembled to allow thorough cleaning.

We can supply from the semi-automatic dosing unit to the complete lines composed by a multi-nozzle linear filler combined with a rotary capper with one or more heads.

Possibility of automatically feeding and positioning caps of various types: screw, flip-top, pressure, with dispenser and pumps.

Compact lines with rotary filling and capping module, with alternating star movement controlled by rotoblock or brushless motor. Possibility of solution with self-adjusting star on the container format, without the need for replacement, with a considerable reduction in format changeover time.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.V.A.

Automatic valve. Suitable for dosing liquid products.

REMARKS: Hopper for product infeed or pipe union for direct suction from drums.

Application with anti-drop shut-off nozzle etc.., it can be installed onto automatic lines.

Multiformat Monoblock MRM900V3

Dosing of liquid and semi-dense products.

Filling and capping line MR-4 MTS-1

Tecnofluss makes complete lines with mixer, turboemulsifier for product preparation.

Filling line Mod. MR-4 Brushless

4-nozzles dosing, output 1800 pieces/h

Monoblock for filling and capping Mod. MRT-12

Dosing with anti-drop nozzles

Multiformat Monoblock MRM900V3

Inclusion of dispenser with stretching device for dispenser pump.

Margarine, like butter, is an emulsion that has a semi-solid consistency at room temperature.

Seven Fluss – dosing systems Tecno Fluss – is specialized in the dosage of Margarine for the Food sector.

Thanks to our volumetric dosers with special feeding system, we can keep the product at the desired temperature for an accurate dosage.

All parts in contact with the product are made of Aisi 316 stainless steel which can be easily removed and washed in the utmost hygiene.

Semi-automatic machines, complete dosing and capping lines for bottles, jars, cups or trays; dosing groups to be integrated into thermoforming machines, by guaranteeing precision and speed in the dosage.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Dosing with gun nozzle for decorations

Dosing Group with 12 + 12 nozzles Mod. GDV

Application on thermoforming machine

Dosing Group with 12 nozzles Mod. GDV

Application on thermoforming machine

Trays line

Application on automatic lines, dosing machine with 2 or 3 nozzles with castle-latch for product spreading and dosing into trays. Output 2000 pieces/h.

Mascara, nowadays more and more widespread in the many variations of colors and properties, is a cosmetic product used in eyelash make-up.

Seven Fluss, thanks to years of experience in the sector with the Tecno Fluss brand, is specialized in the production of linear and rotary dosing machines specific for Mascara.

We offer totally customizable solutions based on the required productivity: from the standard semi-automatic volumetric doser to complete filling and capping lines with robotic systems, that reduce the packaging time of the final product.

To allow a precise and fast dosage, we implement special thread-cut shut-off nozzles with asuction for the special sticks with brush.

Possibility of adding heated systems composed by hoppers with electric resistors and stirrers with scrapers and thrust auger, dosing part executed with heated double wall.

Our rotary filling and capping machines with special stick containment bushes can be equipped with robots and pick & place system for automatic loading and screwing of the brush.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with no-drip nozzle, this application can be put online on automatic systems.

Heating kit for all parts in contact with the product to be dosed.

Dosing and Capping Machine Mod. MM-2

Productivity: 1.500 pcs/h with shuttle-off and no-drip nozzle.

Dosing and Capping Machine Mod. MM-2

Productivity: 1.500 pcs/h with shuttle-off and no-drip nozzle.

Dosing unit VM 60 T.B.P.

Suction no-drip nozzle.

Potato Puree is a creamy food, generally composed of a mixture of potatoes, milk and butter.

Seven Fluss – dosing systems Tecno Fluss – is specialized in the dosing of dense and creamy food products such as Mashed Potatoes.

With our experts, we design and manufacture dosing systems with the final aim of taking care of the final product filling, capping and labeling phases.

We offer specific dosing systems starting from small productions, up to the highest productions with the possibility of implementation, depending on the density of the puree, of heating systems to keep the product at a constant temperature and make the dosing operations easier.

We produce semi-automatic dosing machines and dosing and capping systems for trays on linear or rotary packaging machines. High quality materials easily removable and washable for cleaning operations.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with flat trowel nozzle for stuffing of sandwiches etc.. It can be installed onto automatic lines.

Filling line for Trays

Filling line for spreading

Mayonnaise is a sauce with a creamy and homogeneous consistency, excellent to be combined with numerous dishes.

Seven Fluss, with its historic brand Tecno Fluss, is specialized in the dosage of Mayonnaise for the food sector.

Based on your production needs, we can offer a wide range of solutions: from our standard volumetric dosing machine to more complex automatic in-line dosing systems with filling, capping, metal presence control, labeling, blowing for sanitization, tables for containers loading and unloading upstream and downstream, in case aslo cartesian or scara robots.

Our volumetric dosing units can be connected with other systems for dosage into bags or trays.

We manufacture filling and capping systems for glass containers with twist-off caps or PE containers with top-down screw caps.

All our dosing systems can be easily disassembled for cleaning operations.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with flat trowel nozzle for stuffing sandwiches etc.., This application can be put in line on automatic systems.

Blowing and filling line for glass jars

Blowing machine with twist overturn and filling and capping unit model MRT-12 for twist-off cap.

Blowing, filling and capping line

Line output 3000 pieces/h with metal detector and possibility of weight checking. Suitable for the transport of glass jars from 100 ml to 1 liter and automatic feeding of twist-off caps.

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles Dosing suitable for glass containers and capping with twist-off cap.

Dosing Group with 12 nozzles Mod. GDV

Application on thermoforming machine

Milk, in all its variants, is an indispensable product for the dairy sector.

The Tecno Fluss filling machines of Seven Fluss are specialized in the dosage of Milk, Yogurt and other creamy dairy products for the Food sector.

These types of products require special care during the manufacturing process: with our dosing systems this is possible.

Our equipment can be easily disassembled for cleaning operations, with the possibility of applying CIP washing systems for making machine cleaning even faster.

To make the dosing even more precise, we have designed special anti-foam systems and diving nozzles.

All parts in contact with the product are in Aisi 316 stainless steel.

Manual Cycle

DOSING MACHINE WITH T.V.A. DOSING HEAD

Automatic valve. Suitable for dosing of liquid and foaming products.

REMARKS: Pipe union for product feeding directly from your tank, with foot valve.

Application with anti-foam and anti-drop diving nozzle, possibility of installation onto automatic lines.

Filling line for glass bottles and PE bottles.

Mineral Oils are extracted and refined with the aim of being used as lubrificant. They are often also used to cool some machines and as insulators, due to their non-electrical conductivity.

Seven Fluss, with the historic Tecno Fluss brand, offers dosing and capping solutions for Mineral Oils.

Semi-automatic volumetric dosers and complete filling and capping systems, which can be integrated with labeling.

Filling monoblocks controlled by a brushless motor, with 2, 4, 6, 8 and 10 nozzles combined with single-head capping monoblocks or, for higher productions, with 3, 4 and 5 heads, complete with automatic closure of the caps.

Solution for products in bottles and for products in cans.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle.

This application can be put in line on automatic systems

Filling and capping line Mod. MR-4 MTS-1

Tecnofluss built also complete lines with mixer, turbomixer for products preparation.

Mud, used in the cosmetic and pharmaceutical field by virtue of its many beneficial properties, is a mixture composed of clayey material and a liquid component.

Seven Fluss, with its historic brand Tecno Fluss, produces dosing systems for dense products like Mud.

For the highest productions we make fully customized filling, capping and labeling machines based on the production needs required.

Linear filling monoblocks with one or more nozzles, equipped with pneumatic or electronic volumetric dosers according to requirements, combined with single-head or multi-head capping machines.

Compact rotary filling and capping modules. Possibility to implement automatic laying or sealing of the operculum under the cap.

For lower productions we provide semi-automatic filling systems with a special TBP head, particularly suitable for dosing thick and pasty products. To guarantee a perfect dosage, without dispersion and waste of the product, the solution includes no-drop and thread-cut shut-off nozzles.

All our filling and capping systems are made of high quality materials. The dosing part in contact with the product can be completely and easily removed for cleaning.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and pasty products.

NOTES: Product loading into the hopper with the possibility of stirring produced by scraping blades and cochlea.

Application with a shuttle-off nozzle. This application can be put online on automatic systems.

The mustard, which is creamy and easily spreadable, is a typical accompanying sauce for many dishes.

Seven Fluss, with its historic brand Tecno Fluss, is specialized in the dosage of sauces for the food industry such as mustard.

We create, based on your productivity needs, from the standard semi-automatic dosing unit to more complex automatic dosing systems with filling, capping, labeling, blowing for sanitizing and integration of special tables for loading and unloading at the beginning and end of the line.

Our dosing systems are carefully designed to speed up production times and facilitate cleaning operations, maintaining the scrupulous care of the various phases of filling, capping and labeling of the final product as the final goal.

Dosing in glass jars with twist-off caps, squeeze bottles and single-dose sachets on multi-lanes packaging systems.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with anti-drop shut-off nozzle. This application can be put in line on automatic systems.

Dosing Unit VM 300 TBP

Dosing Unit VM 300 TBP with heated hopper equipped with stirrer. Dosing of Sauces up to 90°

Blowing and filling line for glass jars

Blowing machine with twist overturn and filling and capping unit model MRT-12 for twist-off cap

Tray lines

Application on automatic lines, dosing machine with 2 or 3 nozzles with castle-latch for product spreading and dosing into trays. Output 2000 pieces/h.

Filling line on unit Mod. MR-4

Quick and precise dosing of sauces with output up to 100 pieces per minute

Filling line for Pesto

Heated hopper with horizontal blades stirrer

Dosing application on customer’s line

Castle-latch nozzle for filling with product

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles Dosing suitable for glass containers and capping with twist-off cap.

Monoblock for filling and sealing Mod. TF-15

Suitable for conical and unstackable containers with precut lid

Dosing machine Mod. VM-60 TBP

Installation on packaging machine for trays

Honey, with its dense consistency and generally golden color, is a food rich of properties, so much to be used not only in the food sector but also in the cosmetic and pharmaceutical ones.

Thanks to thirty years of experience in the field, Seven Fluss, with its historic brand Tecno Fluss , is specialized in the dosing of dense products such as Honey.

Based on your production needs, we design customized solutions starting from the semi-automatic dosing unit, up to complete high-speed filling, capping and labeling systems for glass jars with twist-off caps or for squeeze PE packages with flip-top cap.

For reaching a precise dosage, we integrate in our filling systems double-wall insulated hopper or completely heated systems, in order to keep the product warm and avoid honey crystallization.

On request we produce dosing groups model GDV and GD for interface to thermoforming machines, especially suitable for dosing single-dose products with high output.

All our dosing systems are easily removable to ensure a quick cleaning operation.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Honey Filling line

Honey Capping line

Honey Labelling line

Blowing, filling and capping line

Blowing and filling line for glass jars

Blowing machine with twist overturn and filling and capping unit model MRT-12 for twist-off cap

Blowing, filling and capping line

Line output 3000 pieces/h with metal detector and possibility of weight checking. Suitable for the transport of glass jars from 100 ml to 1 liter and automatic infeed for twist-off caps.

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles Dosing suitable for glass containers and capping with twist-off cap.

Dosing Group with 12 nozzles Mod. GDV

Application on thermoforming machine

Nail Polish is used in cosmetics to color, fortify and protect nails. In recent years it has been joined by the Nail Gel, generally used for reconstruction.

Seven Fluss, thanks to years of experience in the cosmetic sector with the historic Tecno Fluss brand, is specialized in the production of dosage systems for products such as Nail Polish.

Depending on the production requirements, we can offer from the semi-automatic volumetric doser to the complete filling and capping lines with robotic systems that allow to reduce packaging times.

Rotary machines with special bushes for stick containment, completed on request by robot or pick & place system for automatic loading and screwing of the brush.

Cartesian robots connected to the dosing unit and associated with multi-impression molds to speed up the filling phase of the sticks. Scara robot to manipulate and position caps and brushes.

For the more limited productions, the semi-automatic dosers are however implemented with the heating system for hopper – cylinder – head and nozzle. The shut-off nozzles with closure inside the cannula guarantee perfect dosing without dripping.

All parts in contact with the product are in Aisi 316 stainless steel and can be completely disassembled for cleaning operation.

Manual Cycle:

DOSING MACHINE WITH DOSING HEAD MOD. T.B.P.

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems.

Olivier Salad, more and more widespread in many countries, is a dish typically composed of diced vegetables, potatoes and mayonnaise although today it is often subject to variations according to the various regional traditions.

Seven Fluss – dosing systems Tecno Fluss – thanks to her long experience in the sector, is a specialist in dosing systems and complete filling and capping lines for Olivier Salad.

With our specific nozzles we can dose the pieces inside the Olivier salad without problems, by maintaining a very precise final dosage.

Each of our filling systems is specifically designed and customized for customer’s needs, based on the quantity and speed of production required.

We offer various types of solutions starting from the semi-automatic dosing unit to complete rotary or linear automatic system. We offer special machines for the thermosealing of trays for small and large productions.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with shut-off thread-cutter nozzle. This application can be put in line on automatic systems

Blowing and filling line for glass jars

Blowing machine with twist overturn and filling and capping unit model MRT-12 for twist-off cap

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles Dosing suitable for glass containers and capping with twist-off cap.

Oil is the Mediterranean dressing for excellence: classic or flavored with various spices inside, both of them can be dosed with Tecno Fluss dosing systems of Seven Fluss.

Our filling machines are specifically designed to safeguard the quality of the product and to keep at the same time a precision of dosing that makes the final result optimal.

Dosing oil is an art and with our dosing systems applied to our filling and capping lines, you can obtain an accurate and precise result, thanks to the experience of our team and the dosing solutions specifically designed for any type of product liquid, dense or doughy.

We manufacture from the simple semi-automatic doser with high dosing precision, equipped with special hopper to mix, for example, oil with aromatic herbs, to complete linear or rotary bottling lines for small and large production according to your needs.

To our filling systems we can add capping modules, with automatic loading, orientation and distribution of the caps also of different types, according to customer’s request.

Possibility of integrating labeling systems with printing of production lot and expiry date.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with anti-drop shut-off nozzle etc.., it can be installed onto automatic lines.

Blowing and filling line for glass jars

Blowing machine with twist overturn and filling and capping unit model MRT-12 for twist-off cap

Filling line for oil

Line output 3000 pezzi/h possibility of weight checking. Suitable for the transport of trays from 100 ml to 1 liter

Filling and capping line Mod. MR-4 + MTS-1

4-nozzles Dosing suitable for glass containers and capping with twist-off cap.

Filling line Mod. MR-4 Brushless

4-nozzles Dosing, output 1800 pieces/h

Panettone and Colomba cakes represent the traditional sweets typical of Made in Italy.

Seven Fluss – dosing systems Tecno Fluss – thanks to years of experience in the confectionery sector, is specialized in filling, injecting and frosting creams and alcoholic liquids within Panettone and Colomba cakes.

Based on the production needs of each customer, it is possible to choose both automatic filling, frosting and injection systems for high production, and semi – automatic volumetric dosers suitable for pastry shops with lower production volumes.

We supply special multi-holes distribution plates to allow a perfect dosage inside panettone and colomba cakes, equipped with castle-latch for nozzle up&down movement that allows a homogeneous distribution of the cream or an alcoholic liquid inside the product.

Our dosing systems allow you to have a quick, precise and efficient production process while preserving the craftsmanship of the final product. We offer automatic dosing solutions for one or more operators.

High quality materials easily removable and washable for cleaning operations.

Manual Cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with multiholes nozzle for stuffing. This application can be put in line on automatic systems.

Stuffing and filling line for panettoni and colombe cakes

Output 1000 pieces/h, quick and precise dosing

Filling line for panettoni cakes

Application of the icing on the panettone. Automatic line, dosing machine with plates for nozzles distribution, with castle-latch for product spreading. Output 1200 pieces/h.

Dosing application with semi-automatic dosing machine

Castle-latch nozzle for injecting and product stuffing.

The Paint is a liquid compound that, once applied to a surface, dries to form a resistant, thin, elastic and waterproof film.

The Seven Fluss Group, with its historic Tecno Fluss brand, offers a wide range of packaging solutions for Paints and Varnishes.

With our volumetric dosing heads we can guarantee high dosing precision, while the use of anti drop and thread-cut nozzles ensures a clean and accurate filling.

In addition to the semi-automatic volumetric dosing unit, we offer complete dosing and capping line solutions, in case also equipped with labeling, capable of satisfying a diversified demand in terms of performance and level of investment.

The automatic solutions can be both linear and rotary, possibly equipped with sealing heads and unstackers of containers and lids. Solutions for packing in bottles, jerrycans and buckets.

All parts in contact with the product are in Aisi 316 stainless steel and can be completely disassembled for cleaning.

Manual cycle

DOSING MACHINE WITH T.B.P. DOSING HEAD

By-pass rotating valve. Suitable for dosing dense and doughy products.

REMARKS: Hopper for product loading with possibility of stirring by scraping blades and augerfiller.

Application with anti-drop shut-off nozzle.

This application can be put in line on automatic systems

Filling and capping line Mod. MR-4 MTS-1

Tecnofluss built also complete lines with mixer, turbomixer for products preparation.

Monobloc Multiformat Mod. MRM-900

Mass dosing system. Prepared for automation with plug-in robot